|

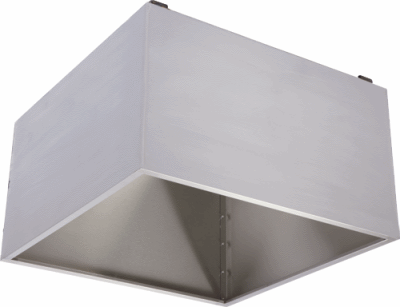

Heat & Condensate Vent Hoods

|

|

Exhaust only hoods to be used over equipment not producing grease laden vapors. Hoods have fully welded

10 gauge corner hanging angle, and hoods over 12' have additional fully welded 10 gauge center hanging angles.

Hat channels and trim strips are installed on top of the hood and have been designed to make the top of the hood

rigid. This allows installation without damaging the top roof panels. This series of hoods has been designed

using the latest in solid modeling software. The manufacturing and assembly processes being used are state of

the art. Each hood goes through a rigorous computerized quality control system that is designed to make sure

the very best products are shipped to the customer.

Hoods can be built with a double wall option. This option is used when switches are needed on the face of the hood.

The double wall option also adds rigidity to the front of the hood at the same time guiding moisture laden air and

heat towards the exhaust riser and away from the front of the hood.

The gutter option (-G), is a full perimeter gutter with a drain for high condensate applications.

430 stainless steel is standard on all panels, and 304 stainless panels are standard on hoods with gutters.

|

|

|

|

|

- Low initial and installation costs.

- Easy access fully welded 10 gauge hanging angles.

- Extremely low exhaust CFM requirement.

- Available in wall type or one-piece island.

- Available with PSP (perforated supply plenum) when make-up air is a must.

- Available with double wall construction when lights are needed; incandescent and fluorescent available.

- 430 stainless used on standard hoods.

- 304 stainless used on hoods with perimeter gutters; primarily in heavy condensation applications.

- Hoods with perimeter gutters have a drain for condensation drainage.

- REM Baffles (Removable condensation baffles) collect and drain condensation into gutters and away from steam source.

|

|

|

|

|

| Configuration |

Light Load

Ovens, Rotisseries |

Heavy Load

Dishwashers |

| Exhaust CFM/Ft. |

Exhaust CFM/Ft. |

| Wall & 1-piece island |

100 |

150 |

|

|

Recommended Duct Sizing:

- Exhaust: Based on 800 FPM

- Supply: Based on 600 to 800 FPM

|

|

|

- Single wall or double wall construction.

- Available in wall type or one-piece island.

- 430 stainless used on standard construction hoods.

- 304 stainless used on hoods with full perimeter gutters.

- Hoods with full perimeter gutters have a drain.

- Hoods that have full perimeter gutters have welded corners.

- Double wall hoods have insulated fronts.

- Double wall hoods offer rigidity and help guide moisture laden air and heat to the riser and away from the front of the hood.

- Incandescent, LED and fluorescent lights are available.

- Hoods are offered in multiple widths: 24”, 30”, 36", 42", 48", 54", 60", 66”, 72”.

- Hoods are offered in multiple lengths between 24" and a maximum of 120".

- Hoods are offered in multiple heights: 12", 24", and 30".

- ETL Sanitation listed and ETL listed.

|

| |

|

|

- Full perimeter gutter with drain.

- Double wall fronts.

- Lighting:

-- Recessed Incandescent

-- Recessed Fluorescent

-- Compact Fluorescent

-- Recessed LED

-- Halogen

- Material options, 304 and 430 stainless.

- PSP (perforated supply plenum) for make-up air applications.

- Custom risers and filter configurations.

- Removable Condensation Baffles, for use in High condensate applications

|

| |

|

|

|

The AM-VHB Model has been certified by ITS. This certification mark indicates that

the product has been tested to and has met the minimum requirements of a widely recognized

(consensus) U.S. and Canadian products safety standard, that the manufacturing site

has been audited, and that the applicant has agreed to a program of periodic factory

follow-up inspections to verify continued performance.

|

|

| |

|

Models AM-VHB are ETL Listed under file number 3054804-001 and complies with UL710, ULC710 and ULC-S646 Standards.

|

| |

|