This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Single Wall & Double Wall

Ductwork

No On-site Welding Required

Universal "V"

Universal "V"Clamp Connections

factory-welded ductwork.

for quality assurance.

Single Wall Ductwork

- ETL Listed to UL Standard 1978 - Grease Ducts and CAN/ULC-S662

- Diameters range from 8" to 36"

- Duct and accessories are made from stainless steel

- Multiple accessories including 45 degree elbow, 90 and Tees

- Access doors available for clean out

- Transition plates available for duct termination at the curb

- Submittals and duct CAD files

- System can be used as a stand-alone duct system and integrated into a kitchen application

- System can be used as part of a fully integrated package designed and pre-engineered for optimum performance with kitchen ventilation equipment

- Factory-built duct saves on installation costs

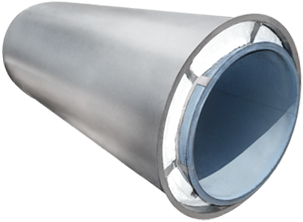

Double Wall Ductwork

- ETL Listed to UL Standard 1978 and UL Standard 2221- Grease Duct Enclosure Assemblies

- Duct sections are constructed of an inner wall and outer wall with insulation in between - inner duct is Single Wall (DW Series) and outer shell is stainless steel

- Inner duct diameters range from 8" to 36"

- Three models are available to meet clearance requirement needs - Model DW-2R, Model DW-3R and Model DW-3Z

- Rated for continuous operation at 500 degrees F and intermittent operation at 2000 degrees F

(Cross Section)

Why Round Ductwork is Superior

Factory-Welded Ductwork (Round)

Traditional Site-Welded Ductwork (Rectangular)

Factory-Welded Ductwork (Round)

Traditional Site-Welded Ductwork (Rectangular)

- Reduced static pressure

- Improved acoustics

- No corners for excessive grease buildup

- Easier to clean

- Faster and cheaper installation

- Factory dye-tested to prevent leaks

- Less surface area

- Requires less insulation when fire wrapped

- Reduced heat gain to the space

Grease Duct Clearances

| DUCT MODEL |

INNER DIAMETER (ID) |

OUTSIDE DIAMETER |

CLEARANCE TO COMBUSTIBLES |

CLEARANCE TO NON-COMBUSTIBLES |

|---|---|---|---|---|

| DW-2R | 8" - 16" | ID+4 | 3/4" | 0" |

| DW-2R | 18" | ID+4 | 1" | 0" |

| DW-3R | 8" - 24" | ID+6 | 3/4" | 0" |

| DW-3Z | 8" - 36" | ID+6 | 0" | 0" |

* DW-2R (18") - 1" clearance to combustibles from the surface of the duct outer shell and 1/4" clearance from combustibles from the tip of the outer V clamp.

- Model 3Z is listed in accordance with Condition A and Condition B of UL Standard 2221 - Condition A represents all installation conditions except for installation within non-ventilated combustible enclosure. Condition B represents installation within a non-ventilated combustible structure.

- Models 2R and 3R are listed in accordance with Condition B of UL Standard 2221 - installation within non-ventilated combustible enclosure

- Duct systems are allowed to penetrate a fire resistance rated floor when using floor support assembly and fire stop kit

Single Wall Product Resources

- Clearances

- Design Guide

- Installation Video Series

- Designing Air Flow Systems

- Duct Sizing Information

- Formulas

- Grease Duct Promotional Handout

- Grease Duct Operation and Installation Manual

- Grease Duct Operation and Installation Manual (French)

- Grease Duct System Certificate of Installation

- Installation Instructions

- Product Information

- Written Specification

- Replacement Parts

Double Wall Product Resources

- Clearances

- Design Guide

- Designing Air Flow Systems

- Formulas

- Double Wall Grease Duct Spec Sheet

- Grease Duct Promotional Handout

- Grease Duct System Certificate of Installation

- Double Wall Operation & Installation Manual

- Double Wall Operation & Installation Manual (French)

- Product Information

- Written Specification

- Replacement Parts

The DW Series has been certified by ITS. This certification mark

indicates that the product has been tested to and has met the minimum

requirements of a widely recognized (consensus) U.S. and Canadian

products safety standard, that the manufacturing site has been audited,

and that the applicant has agreed to a program of periodic factory

follow-up inspections to verify continued performance.

The DW Series has been certified by ITS. This certification mark

indicates that the product has been tested to and has met the minimum

requirements of a widely recognized (consensus) U.S. and Canadian

products safety standard, that the manufacturing site has been audited,

and that the applicant has agreed to a program of periodic factory

follow-up inspections to verify continued performance.

Model DW Series is ETL Listed under file number 3114021, and complies with UL-1978, as well as CAN/ULC-S662.

The Double Wall Ductwork Series has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. Product safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

The Double Wall Ductwork Series has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. Product safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

Models DW-2R and DW-3R are ETL Listed under file number 1000082319SAT-006 EEV and comply with UL1978 and UL2221 Standards.

Model DW-3Z is ETL Listed under file number 1000082319SAT-006 EEV and complies with UL1978, UL2221 and CAN/ULC-S144 Standards.