This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

TANK

Fire Suppression

Electronic Detection

Wet Chemical Suppression

- Faster and more accurate electrical detection

- Monitored, supervised loops on all critical components

- Low voltage interlock for multiple systems

- Battery backup ensures safety even during power outage

- Cloud-accessibility for monitoring functionality and activation

Electronic Fire Detection

Firestat - An electronic, solid state firestat reliably detects fire in the system. If TANK detects a temperature above 360ºF or a rapid rise in temperature, the firestat contacts will close, energizing the fire system.

Electric System with Battery Backup - In the event of a power outage, TANK uses a battery backup to disrupt all appliances through electric gas valves and shunt trip breakers. TANK’s battery backup also powers fire monitoring, detection, and suppression.

Real-Time Monitoring

Microprocessor Based Control - Instant notification of problems with the system

TANK Control Board - TANK’s control board provides all of the necessary monitoring, timing, and supervision functions required for reliable operation. If a fault is detected, an alarm will periodically sound and the "Fire System Activated" light will flash a fault code. The unit's display screen will show the specific fault detected.

Independent Supervised Loops - The supervised loops incorporate both redundancy and fault detection. The firestat and manual activation device are connected to the loops.

24/7 Monitoring - System pressure is monitored at all times to ensure suppression tanks are full of agent and ready to discharge.

monitoring of system components

Wet Chemical Suppression

Overlapping Protection - Overlapping nozzles installed up to 36 inches apart and 35-50 inches above the cooking surface ensure an even and overlapping spray throughout the hazard zone.

Simplified Nozzle Design - Each nozzle’s metal blow-off cap keeps the nozzle tip orifice free of grease build-up and ready to activate at any moment.

User Friendly Design

Total Flexibility - Overlapping nozzles allow for any appliance configuration, keeping your kitchen safe for years to come. Universal spray coverage allows you to swap appliances with confidence as cooking demand or menus change.

Convenience - A factory pre-piped system and optional field hookup streamlines installation and eliminates headaches.

Product Resources

- TANK Quick Reference Guide

- TANK Operation & Installation Manual

- TANK Operation & Installation Manual - Spanish

- TANK Written Specification (PDF)

- TANK Written Specification (Word Document)

- Shop TANK Parts Online

- TANK FDNY COA

- TANK Post-Discharge Procedure

- TANK Maintenance Guide

- TANK Chemical Agent MSDS

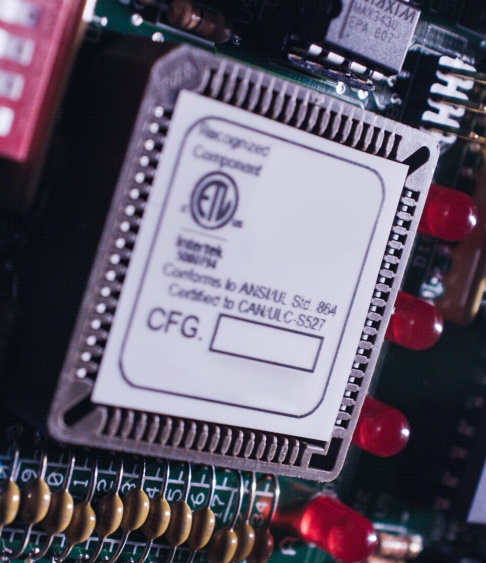

The TANK Fire Suppression System is a UL and ETL Listed system for wet chemical extinguishing system units. The TANK system is UL listed under file number EX27953 to meet requirements of UL 300; ULC Listed to meet requirements of ULC/ORD-C1254.6 and UL/ULC 1254; CE Marked; Meets requirements of NFPA 96 and NFPA 17A. The TANK Fire suppression system is ETL listed under Report Number 104560275SAT-003 to ANSI/CAN/UL/ULC 300.

The control package for TANK Fire Suppression is ETL listed under report number 101196419NYM-001 to the UL Standard 864 and CAN/ULC-S527-11; FDNY Certificate of Approval #5870

This product may be covered by one or more of the following patent number(s): (United States) 8378834, or other U.S. and foreign patents pending.